HV Battery Analyzer:

- Measures individual battery capacity in Charge (CHRG) or Discharge (DSCH) modes

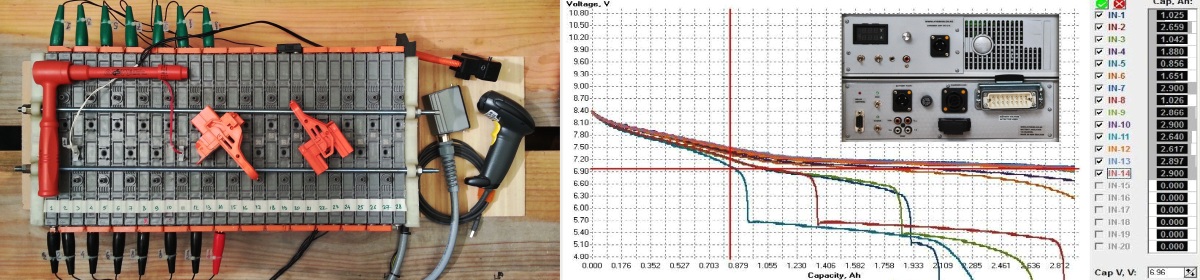

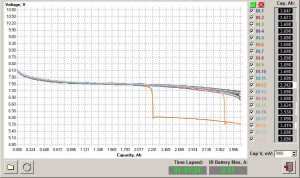

- Provides visual representation of charge and discharge process of the individual modules and their performance in easy to understand colored bars

- Plots graphs

- Stores measured capacity and other parameters in a database to assist in compiling the pack from the modules with the similar parameters

HV Analyzer consists of custom build hardware and proprietary software. We build different version for 14, 19, 20 Channels to test packs comprised up to 40 individual modules.

HV Battery Analyzer measures and records multiple parameters e.g. individual capacities, voltages, time and other metrics.

After test is finished measured capacity of the individual battery is displayed in a bar or chart format.

If you were using conventional methods you will not be able to spot those failed modules in the pack, but our Battery Analyzer does it in an easy way:

Database keeps the records of tested battery packs and measured capacities of the individual batteries (battery modules).

Data is presented in a manageable form and allows compiling new packs from the batteries of similar capacity.

When alarm goes off it activates Voice Alarm, Screen Alarm and cuts off High Voltage Relay Controlled Circuitry (HVRCC) if required.

Alarms could be triggered by the individual battery low/high voltage, over current, over temperature, capacity reached, time lapsed. Alarms could be dynamically deactivated during operation.

HV Battery Analyzer hardware is assembled in a metal enclosure, has LED indicators, switches and cable connectors.

Hardware part is controlled by PC and connects to:

– Battery Pack or part of it, and

– Charger or Dis-charger (Load) depending on the testing mode (CHRG/DSCH)

External Temperature Sensors are optionally connected to the Battery Analyzer and could be attached to the battery pack, installed inside the charger or load.

HV Battery Analyzer measures capacity of batteries connected in series. Each battery may have from 1 to 12 cells inside. Batteries from different applications could be tested.

Watch Video: Testing Complex Main Blocks, Cables and Safety Alarms in action

Watch Video: Battery Test For Dummies – Comparative Test of 20 Prius Modules

Chargers (not offered separate from Analyzers)

NiMH Batteries are charged in a Constant Current (CC) mode.

See few of our custom built chargers on the picture below.

We build specialized chargers. for charging 14, 17, 19, 20, 28, 40* x 7.2 (or 30 x 9.6V) NiMH modules connected in series – e.g. Prius, Prius – C, Aqua, SAI, Camry (1/2 pack), Lexus, Highlander.

Input: 100-240V AC, 50/60Hz – i.e. USA, Canada, Europe, Asia, Oceania

We use Isolated Switch Mode Power Supply (SMPS) Industrial type boards made in Japan and/or South Korea.

For Lexus/ Toyota / Highlander (288V, 40 x 7.2V or 30 x 9.6V) we have Rescue Hybrid Battery charger. Operates from 12V 26A DC

Temperature sensor inside the charger could be monitored by the HV Battery Analyzer to cut of HV circuitry if the charger is overheated (e.g. in case of the cooling fan malfunction).

Current is monitored by the HV Battery Analyzer which will set up alarm and cut of HV circuitry to the battery pack if there is over current.

Charger is connected to the battery pack through the Analyzer.

Different types of loads can be used with Analyzer in discharge mode to measure capacity and battery performance at different discharge currents.